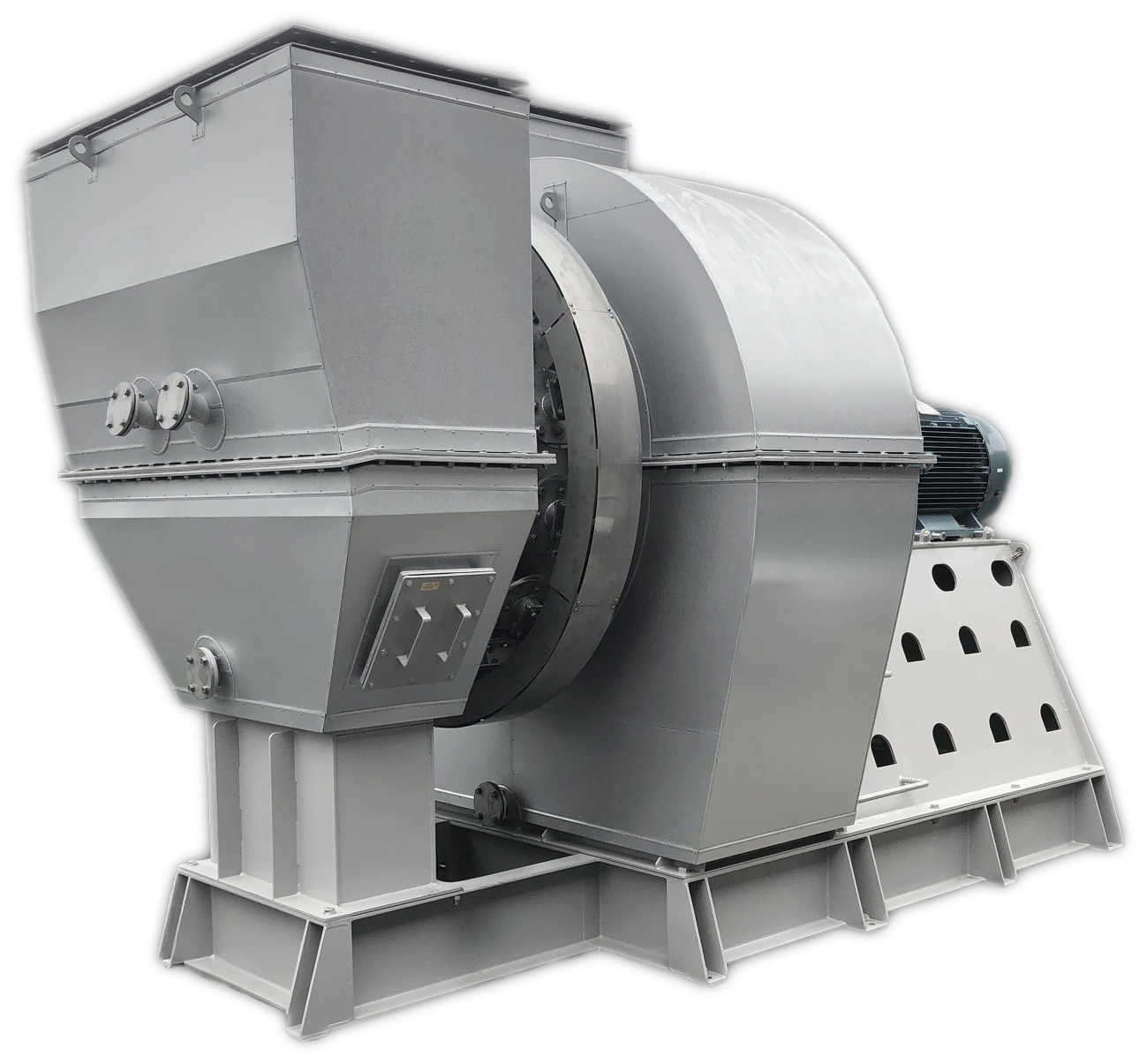

Induced Draft Fans

Certified fans, ensuring safety in areas that require the movement of hot, contaminated or particulate-laden air.

An Induced Draft (ID) Fan from Woodcock & Wilson Ltd offers a high-performance, engineered solution for managing airflow in demanding industrial environments.

Designed to create negative pressure, these fans draw air or gas through a system – making them essential for processes involving hot, contaminated, or particle-laden gases.

With decades of industry expertise, our ID Fans are built to handle extreme conditions such as elevated temperatures, corrosive atmospheres, and abrasive particulates, while ensuring consistent, controlled airflow. Whether you’re operating in power generation, chemical processing, metal production, or renewable energy, our fans are tailored to meet your exact requirements – delivering efficiency, safety, and long-term reliability.

Key Features of an Induced Draft Fan

Our Induced Draft (ID) Fans are designed to perform reliably in harsh industrial environments. Built from high-strength and corrosion-resistant materials, they are capable of withstanding elevated temperatures, chemical exposure, and abrasive particles. Gas-tight casings and high-integrity seals, with optional purging, ensure safe containment of hazardous gases where required.

Each fan is engineered for long-term efficiency, with customisable blade designs to suit a wide range of applications. Oil or water-cooled bearings and wear-resistant components enhance durability, while precise balancing ensures smooth, low-vibration operation. Certified options, including ATEX and IECEx, ensure compliance with international safety standards for high-risk environments.

Download our Induced Draft Fan Spec Sheet

An Induced Draft (ID) Fan is a type of industrial fan used to generate suction pressure that pulls air or gas through a system. The term "induced" refers to the way the fan creates negative pressure to move air through a process rather than forcing it in.

ID Fans are widely used in various industries, particularly in applications requiring the movement of hot, contaminated, or particulate-laden air. Their primary role is to ensure a controlled flow of air and gases in processes such as combustion, filtration, and chemical treatment.

ID Fans must be designed to handle the challenging operating conditions they often encounter. These include:

· Elevated temperatures – Operating in high-temperature environments requires materials and design features that can withstand thermal stress.

· Chemical contamination and corrosion – Fans used in chemically aggressive environments must be made from corrosion-resistant materials.

· Airborne solids and erosion – Industrial gases often contain abrasive particles that can wear fan components.

· Thermal cycles – Repeated heating and cooling can lead to material fatigue and failure if not properly designed.

· Containment of hazardous gases – In some industries, ID Fans must be gas-tight to prevent leaks of harmful substances.

ID Fans are commonly found in:

· Boilers and burners – To maintain optimal combustion efficiency by managing airflow.

· Power plants – Used in Energy from Waste (EfW) plants, coal-fired boilers, and biomass plants.

· Filtration and scrubber systems – To remove particulates and contaminants from industrial emissions.

· Primary industries – Quarrying, minerals processing, and metal production.

· Oil and gas – Used in refining, petrochemical processes, and gas handling.

· Pharmaceuticals and renewables – Supporting clean production environments and energy-efficient processes.

Any fan where the majority of the pressure is on the inlet side can be considered an ID Fan. Their power capacity ranges from a few kilowatts to over a megawatt, depending on the application.